To install an air compressor, first, determine a suitable location and ensure the compressor is level. Then, connect the intake filter, pressure regulator, and drain valve.

Essential Equipment

- Wrenches: Wrenches are essential for tightening and securing various components of the air compressor. They come in different sizes and types, such as adjustable wrenches and socket wrenches, to accommodate different fittings and bolts.

- Screwdriver: A screwdriver is needed to remove or tighten screws and fasteners during the installation process. It is useful when attaching components or adjusting settings on the air compressor.

- Pipe Thread Tape: Pipe thread tape, also known as Teflon tape, is essential for creating a tight seal between threaded connections. It helps prevent air leaks and ensures a secure connection between pipes and fittings.

Optional Equipment

Optional Equipment:

An air compressor can be a versatile tool for various applications. To enhance its functionality, you may consider adding optional equipment to make your work easier and more efficient.

Air Hose:

One essential optional equipment is an air hose. This flexible tube allows you to connect the air compressor to your desired tools or equipment. It should be durable and compatible with the air compressor’s pressure rating. Choose a hose that suits your needs in terms of length and diameter to ensure optimal airflow.

Pressure Regulator:

To control the air pressure output, a pressure regulator is indispensable. It enables you to adjust the air pressure to match the requirements of your specific application. This component ensures that you have precise control over the pressure levels, enhancing the safety and performance of your air tools or equipment.

Air Filtration System:

To ensure the longevity and reliability of your air tools, consider investing in an air filtration system. This equipment helps to remove impurities, such as dust, oil, and moisture, from the compressed air. By maintaining clean and dry air, you can prevent damage to your tools and achieve optimum performance.

Ensure Proper Ventilation

When installing an air compressor, it is crucial to choose a well-ventilated area. The compressor generates heat during operation, so proper ventilation is necessary to prevent overheating. This will help maintain the compressor’s performance and extend its lifespan.

Consider the following points for ensuring proper ventilation:

- Choose a location where there is ample space around the compressor for air circulation.

- Install the compressor in an area with good airflow, away from walls or other obstructions.

- If the selected location lacks adequate natural ventilation, it may be necessary to install a ventilation system to provide fresh air.

By ensuring proper ventilation, you can optimize the performance and efficiency of your air compressor, and minimize the risk of overheating or malfunctioning.

Wear Appropriate Safety Gear

Wear appropriate safety gear

When installing an air compressor, it is crucial to prioritize safety by wearing the right protective equipment. This includes eye protection, which shields your eyes from dust, debris, and flying particles that may be present during installation. Additionally, it is essential to wear ear protection to minimize exposure to loud noise produced by the compressor.

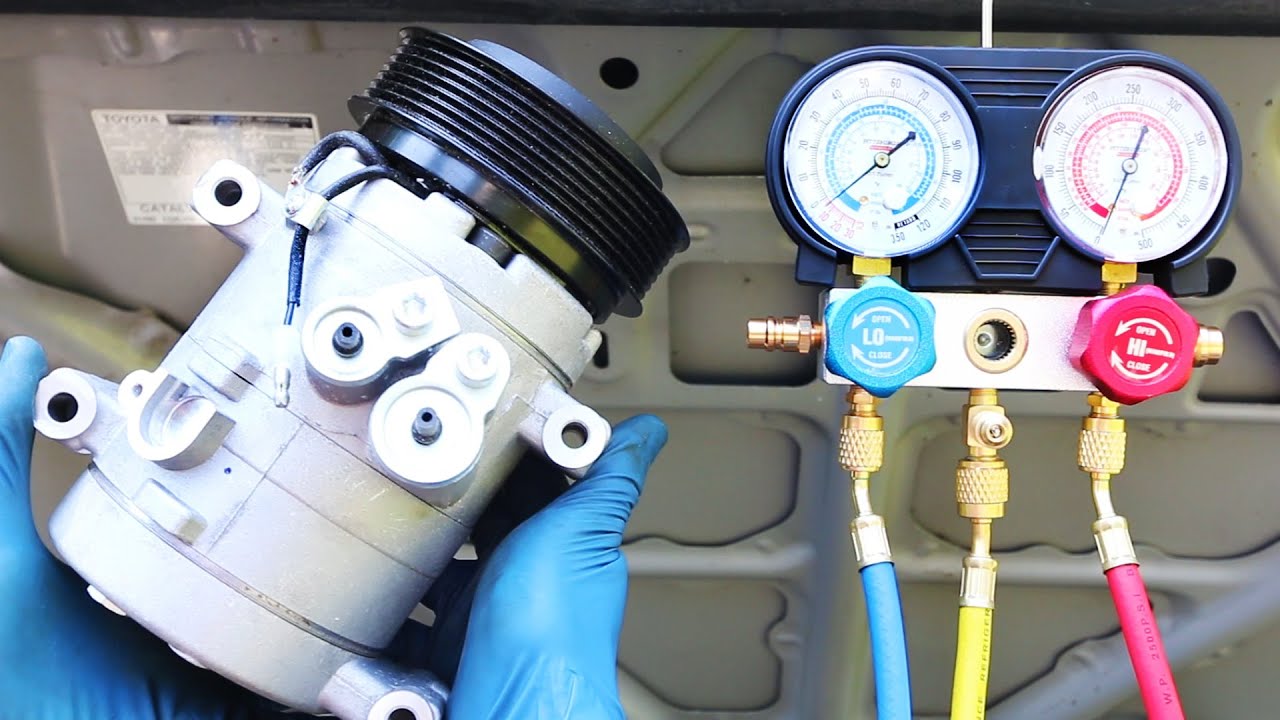

Gloves are also necessary to protect your hands from potential injuries while handling various tools and components. Make sure to choose gloves that offer a good grip and are suitable for the tasks involved in the installation process. Remember, safety should always be the top priority when working with any equipment, so take the necessary precautions and wear the appropriate safety gear to ensure a smooth and secure installation.

Determine The Installation Location

When installing an air compressor, the first step is to determine the installation location. This is important for ensuring optimal performance and noise reduction.

Consider the noise levels when choosing the installation spot. Locate the compressor away from living areas or workspaces to minimize disturbances. Additionally, check if the air compressor has noise reduction features or if it requires additional soundproofing measures.

Another important consideration is ensuring sufficient space for the air compressor. It should have enough room for proper ventilation and maintenance accessibility. Make sure to check the manufacturer’s guidelines for the recommended clearance around the unit.

Prepare The Installation Area

htmlPrepare the installation area

Clear any obstructions and clean the area. Before installing an air compressor, it is important to ensure the designated area is clear of any obstructions. This will help prevent any accidents or damage during the installation process. Take the time to thoroughly inspect the area and remove any objects or clutter that may interfere with the installation.

Mount The Air Compressor

To install an air compressor, start by mounting it using either mounting brackets or bolts. Use mounting brackets to secure the compressor in place, ensuring proper stability. Alternatively, attach the compressor using bolts, making sure they are tight enough to keep the compressor secure during operation.

Credit: www.youtube.com

Connect The Air Intake Line

Connecting the air intake line of an air compressor is crucial for its proper installation. To attach the intake valve securely, it is recommended to use pipe thread tape. This tape helps in creating a tight seal between the intake valve and the compressor, preventing any air leaks.

First, make sure to clean the threads of both the intake valve and the air compressor. This will ensure a smooth connection and reduce the chances of any debris interfering with the seal. Once cleaned, wrap the threads of the intake valve with pipe thread tape in a clockwise direction.

Next, carefully screw the intake valve onto the air compressor, taking care not to cross-thread. As you tighten the valve, the pipe thread tape will help create a tight and secure connection. Make sure not to overtighten as it can damage the threads or cause leaks.

Once the intake valve is properly attached, you can proceed with the other installation steps to set up the air compressor for efficient operation.

Install The Pressure Regulator

Connecting the pressure regulator to the air compressor is an important step in properly installing your air compressor. The pressure regulator allows you to adjust the desired pressure level for your specific needs. To connect the pressure regulator, follow these steps:

- Locate the outlet valve on the air compressor.

- Attach one end of a suitable-sized hose to the outlet valve.

- Connect the other end of the hose to the inlet of the pressure regulator.

- Secure the connection with hose clamps to ensure a tight fit.

- Once connected, adjust the pressure regulator to your desired pressure level by turning the adjustment knob.

- Ensure that the pressure gauge attached to the pressure regulator displays the correct pressure level.

By correctly installing the pressure regulator and adjusting the desired pressure level, you can effectively control the output of your air compressor, ensuring optimal performance for your specific applications.

Attach The Air Hose

To attach the air hose, simply connect one end of the air hose to the air compressor. Make sure it is securely fastened to avoid any leaks or accidents. Then, attach the other end of the hose to the desired tools or equipment that you plan to use with the air compressor. This will allow the compressed air to properly flow through the hose and into the equipment, providing the power and pressure needed for various tasks. Take note of any specific instructions or fittings required for your particular air hose and equipment, as these may vary. Properly connecting the air hose is crucial for the safe and effective use of your air compressor.

Install An Air Filtration System

Install an air filtration system:

Connect the filtration system to the air compressor:

Installing an air filtration system is an essential step for ensuring the proper filtration of air in your air compressor. The filtration system helps to remove impurities such as oil, moisture, and dirt from the air, resulting in cleaner and higher-quality compressed air.

To connect the filtration system to the air compressor, you will need to follow a few simple steps. First, locate the intake port on the air compressor. This is where the filtered air will enter the compressor. Next, attach the intake hose of the filtration system to the intake port of the compressor, making sure it is securely connected.

Once the filtration system is connected, make sure to check for any leaks or loose connections. Tighten any fittings if necessary. Finally, power on the air compressor and monitor the filtration system to ensure it is operating properly.

Perform A Pressure Test

To install an air compressor, start by performing a pressure test. This will help identify any leaks or issues before using the compressor. To begin, turn on the air compressor and let it run for a few minutes to build up pressure. While the compressor is running, check all connections and fittings for any signs of leakage, such as hissing sounds or visible air escaping. Pay close attention to areas where pipes or hoses connect, as these are common spots for leaks.

| Step | Action |

| 1 | Turn on the air compressor |

| 2 | Check for any leaks |

If you notice any leaks, you’ll need to address them before proceeding with the installation. Tighten any loose connections or replace damaged fittings or hoses. It’s crucial to have a properly functioning air compressor to ensure efficient and safe operation. Once you’ve completed the pressure test and addressed any leaks, you can move on to the next steps of installing the air compressor.

Regular Maintenance

Regular maintenance is essential for ensuring the proper functioning of your air compressor. One of the important aspects of maintenance is to regularly check the oil levels. Check the oil levels and ensure that they are within the recommended range. If the oil level is low, add oil to bring it up to the appropriate level. It is also important to clean or replace the air filters as needed. Dirt and dust can accumulate in the air filters over time, which can affect the performance of the compressor. Regularly cleaning or replacing the air filters will help maintain optimal airflow and prevent any damage to the compressor. By following these maintenance practices, you can ensure that your air compressor operates efficiently and lasts for a long time.

Troubleshooting Common Issues

Low pressure can be a common problem when installing an air compressor. To address this issue, several factors need to be considered. Firstly, check the pressure regulator. Ensure that it is set correctly and not limiting the airflow. Additionally, inspect the air filter for any clogs or debris that could hinder the compressor’s performance. Secondly, excessive noise can be disruptive and potentially indicate mechanical issues. Check for loose or worn parts such as belts or bearings. Tighten or replace as necessary. Regular maintenance and lubrication of moving components can also prevent excessive noise. Lastly, air leaks can compromise the efficiency of the compressor. Inspect all connections and fittings carefully. Replace any damaged or faulty seals, gaskets, or hoses. Remember, addressing common issues promptly can ensure the smooth operation and longevity of your air compressor.

Frequently Asked Questions Of How To Install Air Compressor

What Is Needed To Install Air Compressor?

To install an air compressor, you simply need a few essential things: a suitable location, proper electrical connections, an air receiver tank, a pressure regulator, and a compressed air distribution system.

Do You Just Plug In An Air Compressor?

Yes, you can simply plug in an air compressor. It’s easy to use and doesn’t require any complicated setup. Just find an electrical outlet, connect the compressor’s power cord, and you’re good to go.

How Do You Hook Up An Air Compressor To A Car?

To hook up an air compressor to your car, follow these steps: 1. Locate the car’s tire valve stems. 2. Connect the compressor hose to the valve stem securely. 3. Turn the compressor on and allow it to fill the tires to the desired pressure.

4. Once filled, disconnect the hose carefully. 5. Repeat the process for all tires.

Conclusion

Installing an air compressor can seem daunting at first, but with the right steps and tools, it becomes a manageable task. By following the instructions in this blog post, you can successfully install an air compressor in your space. Remember to gather all necessary materials, plan for the location and installation process, and take safety precautions.

With these tips, you’ll be ready to enjoy the benefits of having an air compressor at your disposal. Happy installing!